Materials you can Laser engrave, cut and Mark

The laser is probably the most versatile tool available for marking, etching and cutting. Laser Engraving is highly controllable which gives delicate marking, yet adjustable to give varying effects on a full range of materials. Laser cutting is also accurate on a wide range of organic materials allowing fine detail which could not be achieved by other methods.

The advantage of the laser over mechanical methods of marking and cutting is that the parts or materials do not have to be clamped down as it is all done with light. There is no mechanical interface with the parts being engraved or cut making it stress free such that even the most delicate of materials can be worked on.

The tabs below give an indication of what can be achieved on the most commonly used materials and how they may be used.

Metal – Etching and/or Engraving

The most common use on metals being laser engraved is to add a part number, bar code, QR code and/or identify parts with a product code or logo. The laser engraved method is perfect for this as it can permanently mark a part or item without stressing the component as would happen with traditional engraving.

The nuclear business is a perfect example of laser engraving on metal because full traceability is required on ALL parts that are exposed to a source, no matter how small. Laser marking allows us to engrave serial numbers and part numbers (sometimes including the source) on tiny parts with text so small a magnifying glass is required to read it. Traceability on all medical equipment is to be implemented in the coming year where new legislation will require a QR code, bar code or manufacturers number. Laser engraving is ideal for this, even on surgical steel.

With the precision control of a laser, the speed, power and frequency of the beam can be varied achieving different results from a near black marking to a soft watermark like etch. Deeper engraving can be gained by repeating the etch with multiple passes.

Because of the diversity of metal structures they react differently to the laser giving varied results. Steel would look different to aluminium if the same settings were used but once set for that particular part the last item will look exactly the same as the first. See below list of metals we have engraved.

The most common use on metals being laser engraved is to add a part number, bar code, QR code and/or identify parts with a product code or logo. The laser engraved method is perfect for this as it can permanently mark a part or item without stressing the component as would happen with traditional engraving.

The nuclear business is a perfect example of laser engraving on metal because full traceability is required on ALL parts that are exposed to a source, no matter how small. Laser marking allows us to engrave serial numbers and part numbers (sometimes including the source) on tiny parts with text so small a magnifying glass is required to read it. Traceability on all medical equipment is to be implemented in the coming year where new legislation will require a QR code, bar code or manufacturers number. Laser engraving is ideal for this, even on surgical steel.

With the precision control of a laser, the speed, power and frequency of the beam can be varied achieving different results from a near black marking to a soft watermark like etch. Deeper engraving can be gained by repeating the etch with multiple passes.

Because of the diversity of metal structures they react differently to the laser giving varied results. Steel would look different to aluminium if the same settings were used but once set for that particular part the last item will look exactly the same as the first. See below list of metals we have engraved.

Aluminium

Anodised

Brushed

Cast

Gold Iridite

Hard Coat

Natural

Painted

Powder Coat

Steel

Black Oxide Coated

Cadmium Coated

Carbon

Cast

Chrome Plated

Galvanised

Hardened

Natural

Nickel Plated

Oxide Coated

Spring Steel

Stainless Steel

Surgical Steel

Other Metals

Brass (Natural)

Brass (coated lacquer)

Bronze

Cast Iron

Cobalt

Copper (Natural)

Copper (nickel coated)

Gold

Inconel

Palladium

Silver

Titanium

Wood - Laser Cutting, Engraving and Design

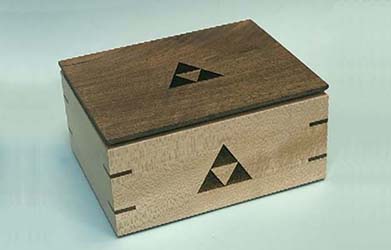

Wood is one of the most versatile medias for the laser to address. Whether cutting, scoring or just plain engraving the effects on wood are so varied.

The precision of the laser allows fine sculpting of wood that other methods of cutting just can’t achieve. See the detail in the “LOVE” bangle in the picture, the fine scrolls would be broken or damaged by any other method. The delicate veins in the butterfly wings can only be achieved with a laser. The technique of cutting with a laser leaves a charred edge, but how much depends on type and thickness of wood. The ideal maximum thickness to cut is 6mm, we can cut thicker but once over the ideal we get more charring and even burn on the edges.

Scoring of wood can work like a fine laser pen carving a line into the wood. The laser follows the vector pattern burning a line into the wood (see picture of pegs). The effect can be varied by speeding or slowing the laser speed, focusing or defocusing the laser thus making the beam wider but less powerful or changing the pulse of the beam. Different effects can be achieved by varying any or all.

Before lasers, pyrography, the art of burning pictures and art into wood using a heated iron was the only way this effect could be achieved. Laser engraving on wood takes it to a whole new level with precision, control and repeatability. The detail that can be achieved, as in this picture of “Great Horned Owl” demonstrates that exquisitely. Not only just the detail in the feathers etc but also the accuracy of the text.

Laser engraved wood is one of our specialities, so whether it is a drawer front for a kitchen unit or the fine detail on a wooden box our expertise is at your disposal. Don’t hesitate to contact us to discuss your requirements.

Acrylic - Laser Cutting, Engraving and Design

Acrylic (Poly(methyl methacrylate) (PMMA)), has many names and may be known as plexiglass or acrylic glass or by trade names such as Perspex, Crylux, Plexiglas, Lucite, Astariglas, Acylite amongst many others. It has many forms but is most commonly used as a lightweight alternative to glass and comes in sheet form of various thicknesses, it is also often cast or moulded. It is generally used transparent but can be obtained in various forms from clear, through various tints to solid colours (nearly every colour of the rainbow).

Solid colours are mainly used in the sign industry and will be often seen in displays and banners, usually for company or shop names. The advantage being it can be back lit creating striking displays.

The advantage of acrylics is it can be easily shaped, cut and engraved making it the ideal media for display purposes and with clever lighting creating a stunning presentation.

These pictures show a couple of different designs of table displays created by us and made for an events company. These and others were fashioned for a whole series of different events.

Here is another example of how acrylic can be used to display items. This one was designed to present an ultra slim bearing for an exhibition with the acrylic stand being laser etched to give details.

We have been laser cutting and etching acrylics since 2002, so if your company has an idea or design that needs to be created, please don’t hesitate to contact us.

Glass - Laser Engraving or Etching

Laser engraving of acrylic or wood is done by the beam etching away the material, but this is not possible on glass so how do you etch?

The manufacture of glass happens at 1700 degrees plus when sand (which is mostly made of silicon dioxide) melts and turns liquid. At this point, two new elements of air and moisture are trapped inside the molten glass.

When a CO2 laser beam contacts the glass, it heats up the silicon (sand) and whatever metal content may be inside the glass formula. While these elements are not affected by the laser, the water and air trapped in the glass expand when heated up, resulting in microscopic fractures on the surface. The ruptures, or fragmenting, is what you see when looking at laser engraved glass. If you look very closely, you can see tiny shards and fractures in the etching. Assorted types of glass (lead crystal, bottle glass etc) can give different results as the surface tension of the glass can vary. For most jobs, with modern laser technology, experience and skill, acceptable engraving on glass is possible but still is not as precise as sandblasting. The advantage of the laser is speed and variation of artwork over the slower process of making stencils and the clean up process after etching by sandblasting.

This image shows a close up of the engraving and the effect on glass. The image was only 25mm wide.

Other - Laser Cutting, Engraving and Marking

There are so many materials that lasers can engrave, etch or mark that it would be impossible to list them here so if you cannot find or see anything you need for your project please don’t hesitate to contact us. Below are some ideas to show a cross section of what is achievable.

One of our customers, Carter Bearings (www.carterbearings.co.uk), offer a unique range of Ceramic and Hybrid bearings which are used widely throughout a host of nuclear, vacuum, cryogenic, high speed, insulating and non-magnetic applications. The structure of these bearings makes it difficult to part mark by traditional methods, but laser engraving works perfectly. We add part number, customer ident and purchase order number for traceability of the bearings.

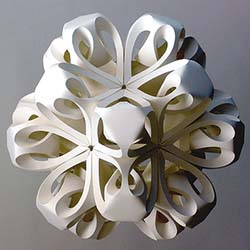

The flexibility of control the laser has means we can cut, score and even etch paper and card. In this example thin card has been cut and scored to be able to produce this beautiful sculpture.

Polycarbonate is a material that is commonly used for covers and enclosures where identification markings, instructions, serial numbers and even QR codes need to be marked. The laser is the perfect tool for such jobs as with the surface discolouration it gives a clear, indelible mark. This sample engraving shows the quality of detail that can be achieved. (see video of it being engraved).

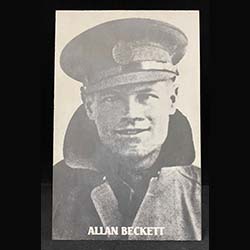

Slate is a natural material that can be etched by both the CO2 & Fibre laser with varying results and textures. This can vary from simple text as on a menu to photographs of loved ones. The more highly polished and smooth the slate, the higher the quality of engraving. This example was engraved onto an A4 size piece of polished slate using the CO2 laser. The scan to produce this was taken from an original WW2 Ilford black & white original photograph (about 60mm x 60mm).

This connector body was machined from PEEK VICTREX 450G UNFILLED for a special application and the connection pin idents needed to be added. Laser engraving was the perfect solution as it clearly marked the material with precision fine marking that could be aligned to ensure that every number was in the correct location.