Lasers

A LASER (acronym for Light Amplification by Stimulated Emission of Radiation) is an optical source that emits photons in a coherent beam. The term has since entered the English language as a standard word, laser, losing the capitalisation in the process. The back-formed verb to lase means “to produce laser light” or “to apply laser light to”.

What is a Laser

The CO2 Laser

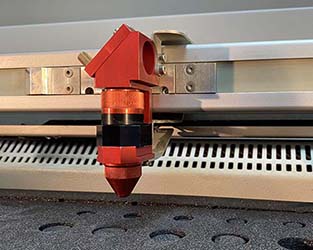

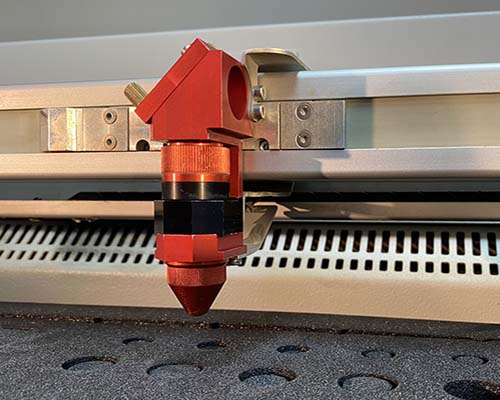

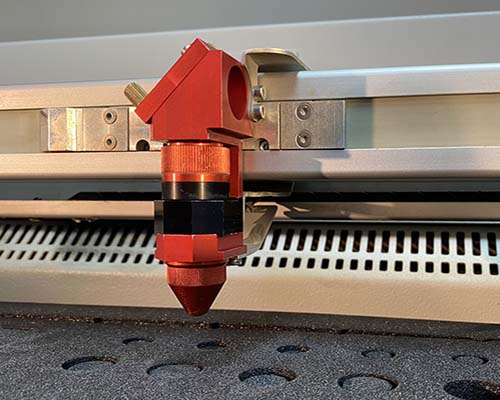

Laser operation occurs when a medium (in our case CO2) is excited within a sealed metal or ceramic tube. The intense beam that is created is focused such that may be used for cutting or “writing” on a variety of materials. Imagine it like taking a magnifying glass out in the sunlight and focusing it to a point to burn a piece of wood.

Laser light is typically near-monochromatic, i.e., consisting of a single wavelength or colour, and emitted in a narrow beam. This contrasts with common light sources, such as the incandescent light bulb, which emit incoherent photons in almost all directions, usually over a wide spectrum of wavelengths.

Lasers are precision tools. A laser never comes into contact with the material it is working on – only its beam does, so damage commonly caused by mechanical machines – touching, dragging, clamping or tearing a material’s surface – is totally avoided. This allows fine gaskets to be cut out of wafer-thin material without distortion or a spiders web to be cut out of a sheet of ordinary paper.

Lasers in the engineering environment are commonly used in such applications as Engraving, Cutting, Marking and even 3D Prototyping.

The carbon dioxide (CO2) laser is the powerhouse for high tech industrial cutting and welding of metals and many other materials. Small CO2 lasers are used for marking metal, wood, and composites, and in medicine and surgery. A ‘small’ CO2 laser produces 10s of watts of beam power and the largest are in the 100 kW range! Its output is at 10.6 um (10,600 nm) or mid-IR (Infrared). This wavelength is about 10 to 30 times longer than the other lasers and is often considered as a source of a heat beam rather than a light beam. At this wavelength, normal glass and plastic optics become totally opaque to the beam so alternatives must be found for the mirrors, lenses, or prisms required by the external optical setup. Divergence/diffraction effects are also increased by this same factor so obtaining a collimated beam is also more difficult.

Many common materials including wood, paper, plastics, composites, and properly prepared metal surfaces absorb quite well at this wavelength so the CO2 laser makes an effective marking, cutting, welding, and heat treating tool.

The CO2 Laser

Laser operation occurs when a medium (in our case CO2) is excited within a sealed metal or ceramic tube. The intense beam that is created is focused such that may be used for cutting or “writing” on a variety of materials. Imagine it like taking a magnifying glass out in the sunlight and focusing it to a point to burn a piece of wood.

Laser light is typically near-monochromatic, i.e., consisting of a single wavelength or colour, and emitted in a narrow beam. This contrasts with common light sources, such as the incandescent light bulb, which emit incoherent photons in almost all directions, usually over a wide spectrum of wavelengths.

Lasers are precision tools. A laser never comes into contact with the material it is working on – only its beam does, so damage commonly caused by mechanical machines – touching, dragging, clamping or tearing a material’s surface – is totally avoided. This allows fine gaskets to be cut out of wafer-thin material without distortion or a spiders web to be cut out of a sheet of ordinary paper.

Lasers in the engineering environment are commonly used in such applications as Engraving, Cutting, Marking and even 3D Prototyping.

The carbon dioxide (CO2) laser is the powerhouse for high tech industrial cutting and welding of metals and many other materials. Small CO2 lasers are used for marking metal, wood, and composites, and in medicine and surgery. A ‘small’ CO2 laser produces 10s of watts of beam power and the largest are in the 100 kW range! Its output is at 10.6 um (10,600 nm) or mid-IR (Infrared). This wavelength is about 10 to 30 times longer than the other lasers and is often considered as a source of a heat beam rather than a light beam. At this wavelength, normal glass and plastic optics become totally opaque to the beam so alternatives must be found for the mirrors, lenses, or prisms required by the external optical setup. Divergence/diffraction effects are also increased by this same factor so obtaining a collimated beam is also more difficult.

Many common materials including wood, paper, plastics, composites, and properly prepared metal surfaces absorb quite well at this wavelength so the CO2 laser makes an effective marking, cutting, welding, and heat treating tool.

Laser engraving

Laser Marking or etching as it is sometimes called, is a process that works by focusing the laser beam through a lens to a pin-point where the considerable heat generated can either penetrate the material to cut it or break the surface to engrave. The control of the laser is such that on full power it can blast its way though 20mm or more of solid acrylic yet by turning the power down it can barely score a piece of card just enough to create a fold line. With specialist control software complicated designs can be created and even pictures can be engraved.

Laser engraving

Laser Marking or etching as it is sometimes called, is a process that works by focusing the laser beam through a lens to a pin-point where the considerable heat generated can either penetrate the material to cut it or break the surface to engrave. The control of the laser is such that on full power it can blast its way though 20mm or more of solid acrylic yet by turning the power down it can barely score a piece of card just enough to create a fold line. With specialist control software complicated designs can be created and even pictures can be engraved.

The Fibre Laser

In technical terms the fibre laser is a laser in which the active gain medium is an optical fibre doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fibre amplifiers, which provide light amplification without lasing. Fibre nonlinearities, such as stimulated Raman scattering or four-wave mixing can also provide gain and thus serve as gain media for a fibre laser.

The Fibre laser in very simplistic terms consists of a laser diode which is the focused through an optical coated fibre which manages and focuses the laser creating a very controlled beam giving a very stable output. This is focused onto a moving mirror (Galvo) system to fine control the beam onto the working area.

The Fibre Laser

In technical terms the fibre laser is a laser in which the active gain medium is an optical fibre doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fibre amplifiers, which provide light amplification without lasing. Fibre nonlinearities, such as stimulated Raman scattering or four-wave mixing can also provide gain and thus serve as gain media for a fibre laser.

The Fibre laser in very simplistic terms consists of a laser diode which is the focused through an optical coated fibre which manages and focuses the laser creating a very controlled beam giving a very stable output. This is focused onto a moving mirror (Galvo) system to fine control the beam onto the working area.

Galvanometer (Galvo) systems for controlling the laser beam is essentially two controlled mirrors (approx.) 90 degrees to each other, the beam is aligned to the first which then bounced the beam off the second then through a focus lens onto the object being engraved. Very similar in principal to those used in light shows but highly accurate. This creates a laser beam from a single point which allows for high speed engraving, the disadvantage is only has a relatively small marking area, typically 120mm – 200mm square.

Lasers

A LASER (acronym for Light Amplification by Stimulated Emission of Radiation) is an optical source that emits photons in a coherent beam. The term has since entered the English language as a standard word, laser, losing the capitalisation in the process. The back-formed verb to lase means “to produce laser light” or “to apply laser light to”.

What is a Laser

The CO2 Laser

Laser operation occurs when a medium (in our case CO2) is excited within a sealed metal or ceramic tube. The intense beam that is created is focused such that may be used for cutting or “writing” on a variety of materials. Imagine it like taking a magnifying glass out in the sunlight and focusing it to a point to burn a piece of wood.

Laser light is typically near-monochromatic, i.e., consisting of a single wavelength or colour, and emitted in a narrow beam. This contrasts with common light sources, such as the incandescent light bulb, which emit incoherent photons in almost all directions, usually over a wide spectrum of wavelengths.

Lasers are precision tools. A laser never comes into contact with the material it is working on – only its beam does, so damage commonly caused by mechanical machines – touching, dragging, clamping or tearing a material’s surface – is totally avoided. This allows fine gaskets to be cut out of wafer-thin material without distortion or a spiders web to be cut out of a sheet of ordinary paper.

Lasers in the engineering environment are commonly used in such applications as Engraving, Cutting, Marking and even 3D Prototyping.

The carbon dioxide (CO2) laser is the powerhouse for high tech industrial cutting and welding of metals and many other materials. Small CO2 lasers are used for marking metal, wood, and composites, and in medicine and surgery. A ‘small’ CO2 laser produces 10s of watts of beam power and the largest are in the 100 kW range! Its output is at 10.6 um (10,600 nm) or mid-IR (Infrared). This wavelength is about 10 to 30 times longer than the other lasers and is often considered as a source of a heat beam rather than a light beam. At this wavelength, normal glass and plastic optics become totally opaque to the beam so alternatives must be found for the mirrors, lenses, or prisms required by the external optical setup. Divergence/diffraction effects are also increased by this same factor so obtaining a collimated beam is also more difficult.

Many common materials including wood, paper, plastics, composites, and properly prepared metal surfaces absorb quite well at this wavelength so the CO2 laser makes an effective marking, cutting, welding, and heat treating tool.

Laser engraving

Laser Marking or etching as it is sometimes called, is a process that works by focusing the laser beam through a lens to a pin-point where the considerable heat generated can either penetrate the material to cut it or break the surface to engrave. The control of the laser is such that on full power it can blast its way though 20mm or more of solid acrylic yet by turning the power down it can barely score a piece of card just enough to create a fold line. With specialist control software complicated designs can be created and even pictures can be engraved.

The Fibre Laser

In technical terms the fibre laser is a laser in which the active gain medium is an optical fibre doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fibre amplifiers, which provide light amplification without lasing. Fibre nonlinearities, such as stimulated Raman scattering or four-wave mixing can also provide gain and thus serve as gain media for a fibre laser.

The Fibre laser in very simplistic terms consists of a laser diode which is the focused through an optical coated fibre which manages and focuses the laser creating a very controlled beam giving a very stable output. This is focused onto a moving mirror (Galvo) system to fine control the beam onto the working area.

Galvanometer (Galvo) systems for controlling the laser beam is essentially two controlled mirrors (approx.) 90 degrees to each other, the beam is aligned to the first which then bounced the beam off the second then through a focus lens onto the object being engraved. Very similar in principal to those used in light shows but highly accurate. This creates a laser beam from a single point which allows for high speed engraving, the disadvantage is only has a relatively small marking area, typically 120mm – 200mm square.