Laser Cutting

Cutting of materials, especially accurately, has been the engineers dream, striving for the ultimate tool. As technology moves on it has become apparent that there will never be a single machine to do this but choosing the correct tool for the job has become more complicated as there are so many overlaps with tools and techniques.

One customer has a focus in precision engineering and has a requirement to put 500 marker lines on a small electric motor fly wheel which is used in a piece of specialist equipment. This is so that sensors can pick up the rotation to control the speed. We helped in the initial development trials engraving different numbers of lines until they achieved the ultimate design. We now get regular orders on all new motors. The picture shows two flywheels that have been engraved.

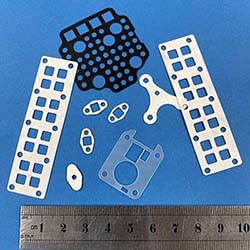

The advantage of laser cutting over other methods is there is no need to clamp the job/material as there is NO tool dragging since everything is done by a beam of light. This means there is no damage or stress to the material being cut which allows us to be able to work on fine materials. See some of the items we have cut in past, for example small gaskets for wind tunnel models and card cut-outs through to acrylics for scientific equipment.